SludgeMunkey

New member

- Joined

- Nov 11, 2008

- Messages

- 2,299

- Reaction score

- 101

- Points

- 0

- Location

- Bellevue, Nebraska

- Country

- United States

- Display Name

- Johnny O. Farnen

Most aquarium air pumps are diaphragm pumps, meaning that a switching transformer is used to move a flexible part on a valve to slightly compress air and give it positive pressure relative to the atmosphere.

The transformer works by using electricity (115V North America, 220V everywhere else) to rapidly turn an electromagnet off and on. When the electromagnet is on a permanent magnet (or in some cases just a block of ferrous metal) to quickly move to the northern magnetic pole of the transformer. When the magnet is off the block moves quickly back to its home position. This block is mounted on an arm with a fixed pivot point (or in some designs a flexible arm). The diaphragm is attached to this arm and is alternately stretched or compressed. The diaphragm is attached to a one way automatic pressure release valve. This allows air to enter the pump from any direction, but only allows it to exit out of one specific point.

This is a relatively simple and efficient design for aquarium use, however it has a major fault that can cause it to wear out quickly if not installed properly. All diaphragm pumps are meant to function with positive pressure on the exit end. That is, you should not run the pump without the air line being under water. The pump will break in a very short time if "run dry" because the diaphragm is being stretched and flex more than it would with a system under pressure, resulting in holes that prevent air from being pumped. Likewise if too much back pressure is present the pump will not be able to over come the water pressure and move air and the diaphragm will also rupture.

With Caudates, we often need an air stone present in our tanks, but do not want the excessive water current created by an airstone directly off the pump line. There are many ways to deal with this excessive current and still provide proper airation, howvere many of them are quick fixes and can cause damage to the pump.

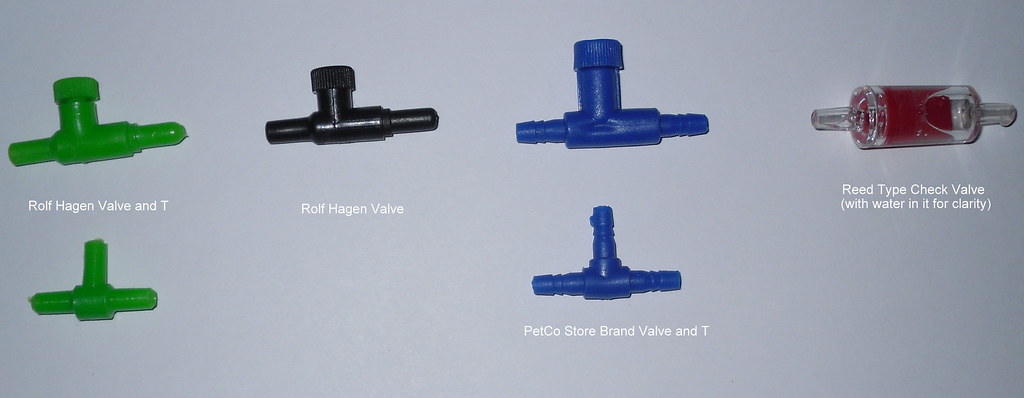

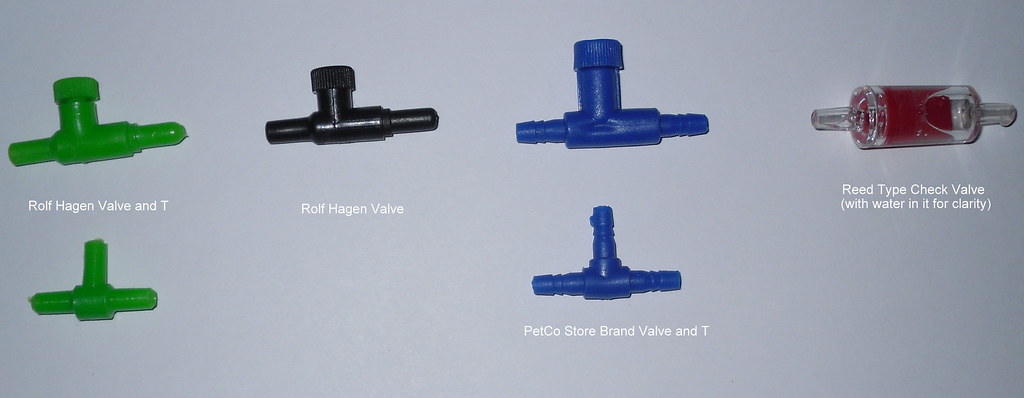

The safest way to regulate air stones with the least risk of damage to your pump, your tank, and your home's electrical system is inexpensive and easy to do. You will need a "T" junction, a regulator valve, some extra airline, a pump and an air stone. The following picture shows the valves and junctions from a few manufacturers.

A reed type check valve only permits flow in one direction and prevents water from siphoning back to you pump in the event of power failure. Most have a directional arrow molded on them to ensure proper installation. "T" junctions are just a three way connector. A valve is usually a plastic needle type, but there are miniature ball and gate valves also.

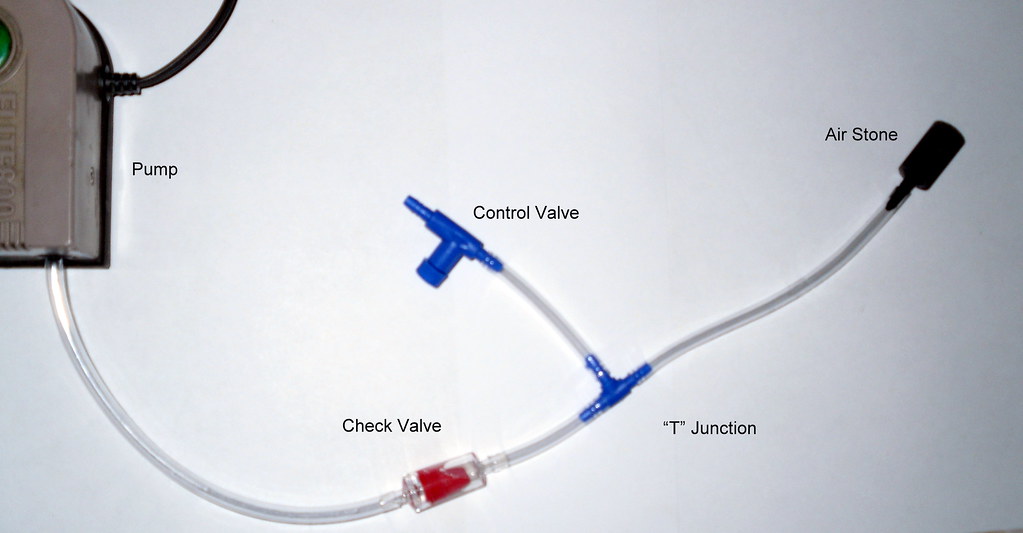

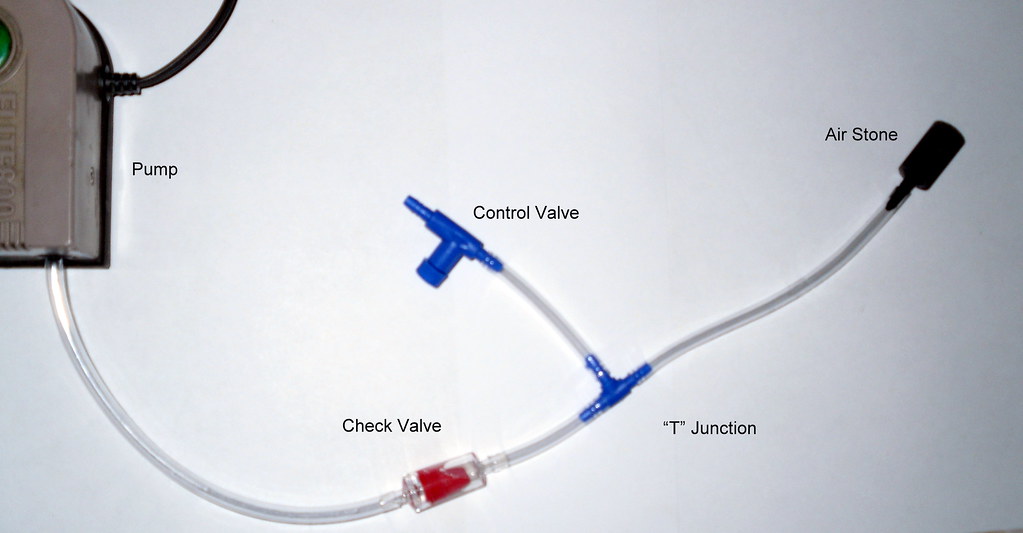

Here is the proper installation of each piece. Please note that the tubing pictured can be any length anywhere in the circuit, it's just short here for clarity.

Notice where the water is visable in the red check valve? I added the water to clearly show the proper way to install these. If installed backwards, it can damage your pump. The regulating valve is installed in the "T" before the air stone to provide pressure control without causing too much back pressure on the check valve or the pump. Once you have this set up installed in your tank (only the airstone goes in the tank I should note!) Make sure your regulating valve is closed, and turn on your pump. Slowly open the regulating valve untill you have the amount of bubbles you want in your tank. The excess pressure will bleed off at the regulating valve, thus preventing damaging back pressure to your pump diaphragm.

Another advantage to this set up is that as the pump ages and the diaphragm stretches slightly, you can adjust the system at the valve to maintain proper flow. This circuit will greatly exted the operating life of your pumps!

The transformer works by using electricity (115V North America, 220V everywhere else) to rapidly turn an electromagnet off and on. When the electromagnet is on a permanent magnet (or in some cases just a block of ferrous metal) to quickly move to the northern magnetic pole of the transformer. When the magnet is off the block moves quickly back to its home position. This block is mounted on an arm with a fixed pivot point (or in some designs a flexible arm). The diaphragm is attached to this arm and is alternately stretched or compressed. The diaphragm is attached to a one way automatic pressure release valve. This allows air to enter the pump from any direction, but only allows it to exit out of one specific point.

This is a relatively simple and efficient design for aquarium use, however it has a major fault that can cause it to wear out quickly if not installed properly. All diaphragm pumps are meant to function with positive pressure on the exit end. That is, you should not run the pump without the air line being under water. The pump will break in a very short time if "run dry" because the diaphragm is being stretched and flex more than it would with a system under pressure, resulting in holes that prevent air from being pumped. Likewise if too much back pressure is present the pump will not be able to over come the water pressure and move air and the diaphragm will also rupture.

With Caudates, we often need an air stone present in our tanks, but do not want the excessive water current created by an airstone directly off the pump line. There are many ways to deal with this excessive current and still provide proper airation, howvere many of them are quick fixes and can cause damage to the pump.

The safest way to regulate air stones with the least risk of damage to your pump, your tank, and your home's electrical system is inexpensive and easy to do. You will need a "T" junction, a regulator valve, some extra airline, a pump and an air stone. The following picture shows the valves and junctions from a few manufacturers.

A reed type check valve only permits flow in one direction and prevents water from siphoning back to you pump in the event of power failure. Most have a directional arrow molded on them to ensure proper installation. "T" junctions are just a three way connector. A valve is usually a plastic needle type, but there are miniature ball and gate valves also.

Here is the proper installation of each piece. Please note that the tubing pictured can be any length anywhere in the circuit, it's just short here for clarity.

Notice where the water is visable in the red check valve? I added the water to clearly show the proper way to install these. If installed backwards, it can damage your pump. The regulating valve is installed in the "T" before the air stone to provide pressure control without causing too much back pressure on the check valve or the pump. Once you have this set up installed in your tank (only the airstone goes in the tank I should note!) Make sure your regulating valve is closed, and turn on your pump. Slowly open the regulating valve untill you have the amount of bubbles you want in your tank. The excess pressure will bleed off at the regulating valve, thus preventing damaging back pressure to your pump diaphragm.

Another advantage to this set up is that as the pump ages and the diaphragm stretches slightly, you can adjust the system at the valve to maintain proper flow. This circuit will greatly exted the operating life of your pumps!